Fimor Serilor HR1 Mono Layer (HIGH RESISTANCE SQUEEGEE)

Serilor®HR is a special polyurethane blade with exceptional combined resistance to chemicals and abrasion. It was developed to withstand the toughest applications in screen printing and to have a long shelf life in most environments.

Serilor®HR blades are manufactured with a centrifugation process to avoid bubbles and craters in the material and to bring optimal homogeneity to the compound, even at the core of the material and after grinding. Our exclusive computer controlled casting process guarantees batch to batch consistency. Each serilor® HR blade is inspected for edge quality and profile.

Advantages:

• Maximum resistance to chemicals

• Maximum resistance to abrasion

• High environment stability (temperature, humidity)

• Sharpens well

• Individual package protects from light and dust

• Individual batch and reference ink jet marking on blade

• High test inspection for aspect defects

Applications:

• Graphics multi-purpose

• Graphics specialities (electronics, industrial etc….)

• Object / Container printing

• Automated textile printing

• Manual or automatic equipment use

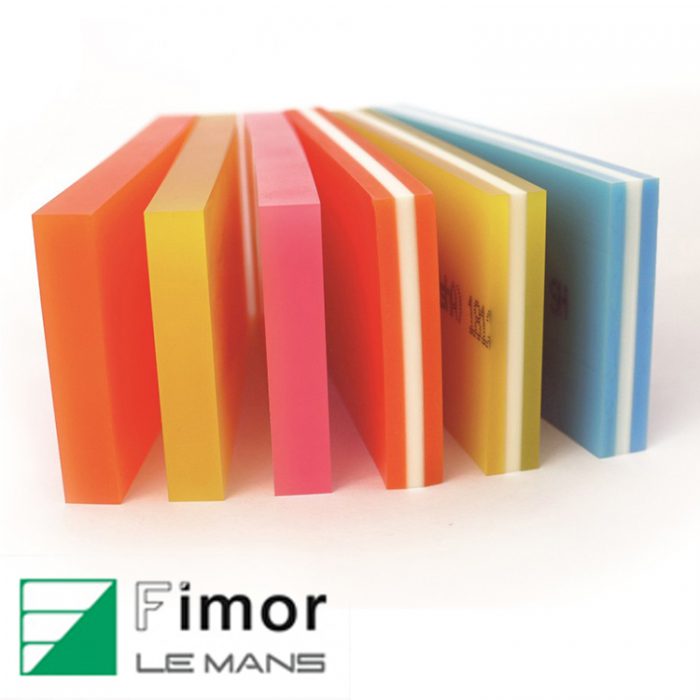

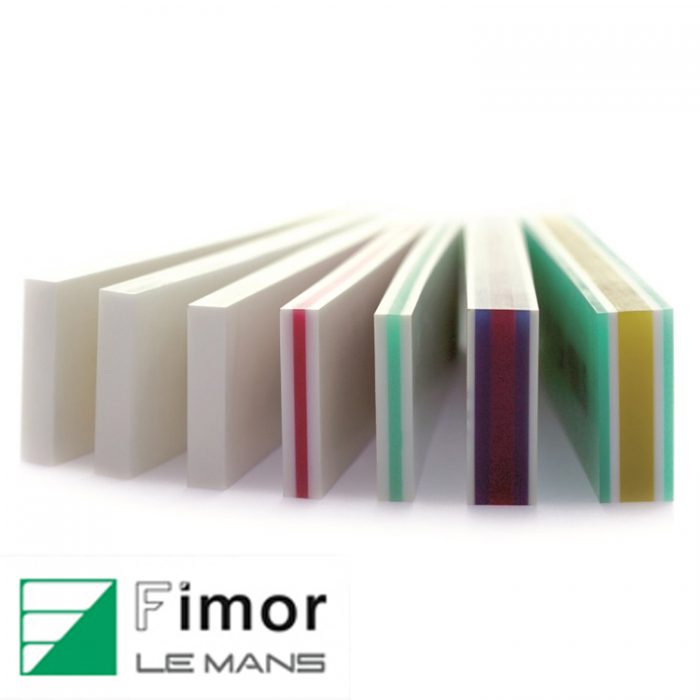

Standard Hardnesses:

• Soft 65shA white

• Medium 75shA white

• Hard 85shA white

• 60,70,80,90 and other durometers are available as specials

PO: Straight Square Edge

P1: Double Bevel + Flat land 60° angle + 1mm flat (±0,5mm)

P2: Single bevel + flat land 45° angle + 1mm flat (±0,5mm)

P3: Round angle

P5: Double Bevel (V type) 60° angle

P6: Single Bevel 45° angle

D: “Diamond” square profile (±0,3mm)

| Specifications | Tolerances | ||

| Length | 3660 mm / 12 Ft | ≥ 3640mm | |

| Width | < 50mm | ± 1,0 mm | |

| ≥ 50mm | + 1/-2 mm | ||

| Thickness | 4-12 mm | +0,4mm / -0,4mm | |

| Hardness | 60 to 90 shA | ± 3 shA no more than 2 shA between the sides of a squeegee | |